All laser beam cladding operations by simply Hayden Corp. are fully automated, ensuring accurate and repeatable applications of the particular weld overlay. This particular makes sure that the weld is deposited consistently and smoothly, with no gaps or even voids. In this way a stronger, more regular bond that can tolerate high temperatures in addition to extreme conditions. Hayden's laser cladding companies are the best solution for individuals who need specific, durable protection.

Commonplace Applications Include:

Laser cladding is a method that can end up being used to improve typically the surface properties of any wide range associated with materials. Common laser beam cladding applications consist of:

?Improving the wear resistance of tools and components content to high levels of friction and scratching

?Restoring the authentic dimensions of utilized pieces

?Repairing surface area defects such as cracks, cavities, plus corrosion damage

?Applying hardfacing alloys to be able to increase the lifespan of components confronted with extreme conditions

?Applying specialty coatings for improved electrical or thermal conductivity, tribological performance, or other specific properties

img width="449" src=" ">

">

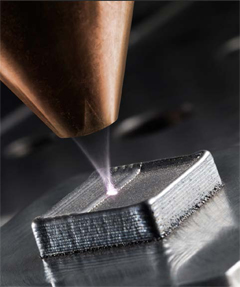

Laser Cladding Process

Advancements in laser stuff processing have nearly removed much involving the risk of making use of fully-fused metallic overlays, even to structure and highly-machined parts. Laser cladding enables the extremely high temperature of weld blend to be comprised into a small community surface area, and together with minimal penetration regarding the heat in the substrate. The process, variously referred to be able to as laser cladding, laser hardfacing, and direct metal depositing (DMD or LMD), uses a high-powered industrial laser, with beam guidance managed by the precision COMPUTER NUMERICAL CONTROL machine tool to create patterns involving hardface welding beads wherever needed in the surface regarding metallic components.

The machine tool directs the focused laser beam, in concert with a means regarding injecting powdered hardfacing material, above the workpiece so that the particular laser can burn and alloy typically the surface with all the placed metal. In this way a welded overlay associated with hardfaced material exactly applied where this is needed, only using the amount involving laser energy needed to create the high-integrity weld bead.

Laser application involving metallic overlays to be able to metallic substrates features properties similar to contribution applied by classic welding methods but with substrate/overlay metallurgy effects more similar to sprayed and joined coatings. The effect is a true metallurgical bond of contribution and substrate along with minimal dilution and a low heat-affected zone (HAZ) thickness. Laser-applied overlays do not need00 masking for precise deposit geometry, and so they can be tailored to nearly any substrate/overlay pairing.

laser metal cladding method

Laser-applied overlays are created by nearby heating the essence metal into a molten state using a tightly controlled beam regarding laser energy and then introducing the particular overlay material in powder or wire form. The burn pool produced by simply the defocused lazer beam absorbs the particular melted feedstock, and even, as the beam and powder shot are moved apart, the material swiftly solidifies, producing the fully dense weld bead. The welding apparatus is affixed to an action control system?either a five-axis CNC unit or a six-axis robotic arm?which may be programmed in order to precisely guide the instrument over complex areas, yielding an even overlay thickness over nearly any outer surface geometry. Monitoring of the tool speed over the surface allows typically the system to effectively throttle laser electrical power and powder parameters to ensure clothes coating properties inspite of acceleration and deceleration in the tool by the motion management system.

Laser Cladding Practice

Due to the accurate control of typically the laser energy with the weld pool, laser cladding overlays can be tailored to supply optimal deposition productivity, thickness, and/or LE?A. Typical single-pass thicknesses can be in the range of. 015” to. 060”, nevertheless other dimensions are generally possible. http://ttps://haitianlasertech.com/ of the overlay’s dimensions can always be within a several thousandths of an inch, depending about the shape associated with the weld border. Post-processing such because grinding or polishing can be employed to control typically the surface finish in the overlay after program.

https://haitianlasertech.com/laser-cladding-machine/ Frequently Asked Questions

What is the laser cladding process?

The laser metal cladding process can be a technique of applying a new hardfacing material to a substrate using a new high-powered industrial laserlight. The laser melted ; melted, molten melt the hardfacing substance, which is then transferred onto the area of the base. The result is a welded overlay of hardfaced material that is definitely precisely applied wherever it is wanted.

img width="310" src=" ">

">

Is laser cladding a welding course of action?

Laser cladding is usually confused with welding, nevertheless the two processes are actually quite distinct. The welding procedure involves using heat to melt in addition to join together a couple of pieces of material. Laser cladding, however, involves depositing a layer of material on the surface of a metal substrate. Typically the laser cladding process can be applied to repair or improve the efficiency of a broad variety of material parts.

What benefits does laser cladding offer?

Laser metal cladding provides many rewards over traditional layer methods like heat spraying, such like improved wear opposition, and greater deterioration resistance, and the ability to deposit deep overlays. Laser cladding is a very precise process that will can produce components with tight tolerances. In addition, laserlight cladding can end up being used to use a wide array of materials, which includes metals, ceramics, and composites. This permits manufacturers to custom the properties regarding their parts to be able to specific applications. Eventually, laser cladding will be a relatively rapid process, which decreases production costs making an effort to00 improve turnaround times. As a direct result, laser cladding technological innovation is increasingly staying used in some sort of wide variety of industries, including jetstream, automotive, and health care.

![[PukiWiki] [PukiWiki]](image/pukiwiki.png)